Maximize Efficiency using an Inventory Management System (IMS)

Managing inventory may be difficult, especially as your firm grows and needs rise. Whether you're a retailer, manufacturer, or wholesaler, keeping the appropriate quantity of inventory is critical. That's where an Inventory Management System (IMS) comes in to help simplify and automate your inventory process. Let's talk about what an IMS is, how it works, and why it's essential for your business.

What is an inventory management system?

An Inventory Management System (IMS) is a software system that enables organizations to measure, manage, and improve their inventory in real time. It automates operations like as stock tracking, reordering, and reporting, resulting in fewer mistakes, more precise stock levels, and less manual work.

Businesses may optimize operations by integrating an IMS, ensuring they have the correct products at the right time and avoid overstocking or running out of commodities. Whether you have a single site or several warehouses, IMS provides complete inventory control, saving you time and money.

How does an IMS work?

An IMS employs many basic procedures to properly manage inventory:

- Data Entry and Integration: Inventory data is entered manually, via barcode scanning, or through integration with e-commerce platforms, POS systems, and financial applications. This establishes a centralized center where you can track inventory in real time.

- Real-Time Inventory Tracking: The IMS constantly updates stock levels as things are added, removed, sold, or transported between locations. This allows you to eliminate stock inconsistencies and keep your records correct.

- Automated Reordering: When stock reaches a certain minimum level, the system produces purchase orders or notifies you to reorder from suppliers. This eliminates stockouts and guarantees that you never lose a sales opportunity due to insufficient inventory.

- Supply Chain Coordination: The IMS monitors supplier performance, delivery times, and lead times. It improves your supply chain by ensuring that merchandise arrives on schedule, minimizing delays, and assisting you in negotiating better terms with suppliers.

- Inventory Analytics and Forecasting: One of an IMS's most useful characteristics is its capacity to analyze past data and predict future trends. By studying your sales habits, the system can forecast demand, allowing you to store appropriately and decrease surplus inventory.

Why Does Your Business Need an IMS?

The benefits of using an IMS extend far beyond simply knowing how much stock you have. Here are some of the main reasons why your organization might consider adopting an IMS:

1. Improved accuracy and reduced errors.

Manual inventory tracking is prone to human mistake, resulting in incorrect stock levels and consequent losses. With an IMS, all procedures are automated, guaranteeing that your data is always up to date and correct.

2. Improved efficiency.

By automating common processes like reordering, inventory counting, and reporting, an IMS allows your personnel to focus on other aspects of your organization. This enhanced efficiency allows you to grow operations without having to hire extra employees.

3. Cost savings.

An IMS allows you to avoid costly overstocking or stockouts. Maintaining proper inventory levels helps to eliminate unnecessary storage expenses and waste from unsold items. The technology also allows you to track slow-moving commodities and create sales promotions to move them.

4. Enhanced customer satisfaction.

Nothing annoys customers more than discovering that a product is out of stock after they have made an order. With an IMS, you can ensure that you always have the things your consumers require, resulting in higher customer retention and repeat business.

5. Improve Decision Making with Data-Driven Insights.

An IMS produces extensive information on inventory movements, sales trends, and supplier performance. These insights enable you to make educated decisions, such as enhancing your product offers or strengthening supplier connections.

Key Features of a Modern IMS

A well-designed IMS offers a range of features that make it an indispensable tool for businesses:

- Multi-Location Support: Manage inventory across multiple warehouses or stores with ease.

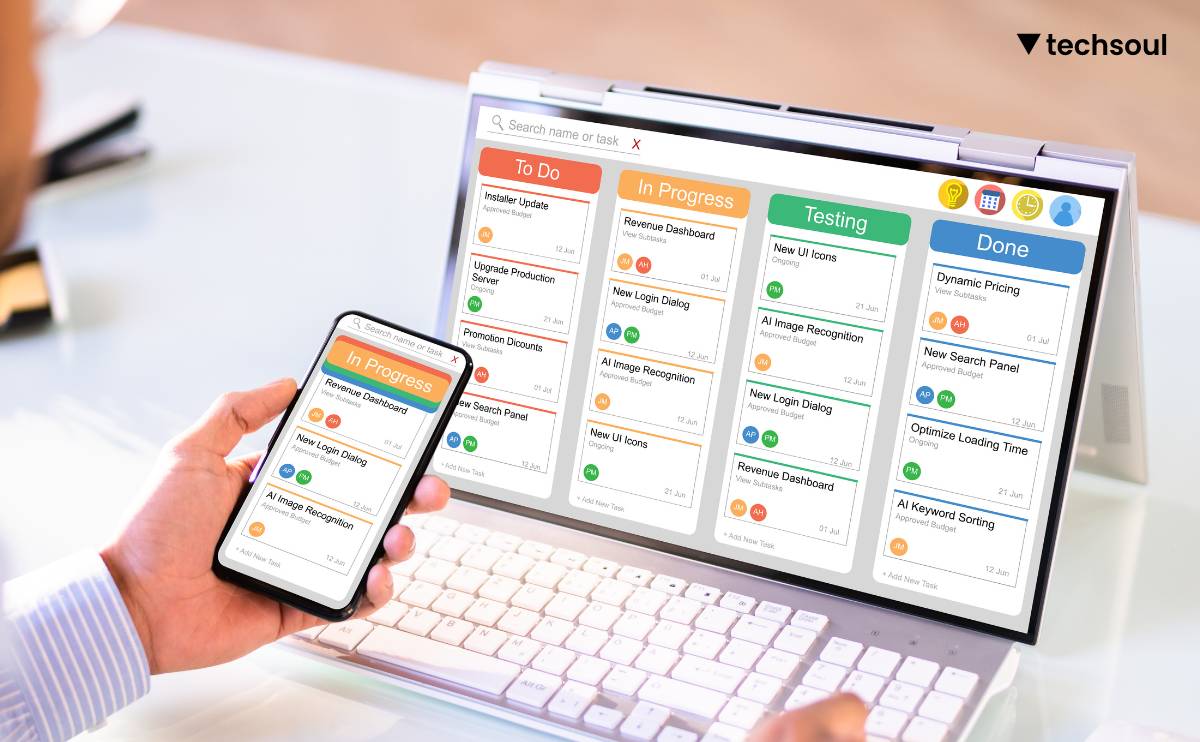

- Mobile Access: Track and manage your inventory on the go through mobile apps.

- Barcode & RFID Integration: Simplify stock management by integrating barcode scanning and RFID technology.

- Customizable Alerts: Set up automatic notifications for low stock levels, reorder points, or delayed shipments.

- Seamless Integration: Connect your IMS to other business systems like e-commerce platforms, POS, and accounting software for a unified approach.

How to Choose the Right IMS for Your Business

When selecting an IMS, consider the following factors:

- Scalability: Ensure the system can grow with your business as you expand.

- Ease of Use: The interface should be intuitive, allowing your team to adopt it quickly.

- Customization: Look for a system that can be tailored to your specific business needs.

- Integration Capabilities: The ability to integrate with existing systems (e.g., ERP, POS) is crucial for streamlined operations.

- Support and Training: Opt for an IMS provider that offers comprehensive customer support and training for your team.

The Future of Inventory Management

As businesses continue to evolve, so does the technology used to manage inventory. The future of IMS lies in further automation, artificial intelligence, and predictive analytics. These advanced features will enable businesses to respond to changes in the market quickly and stay ahead of competitors.

Final Thoughts: Optimize Your Inventory with IMS

Implementing an Inventory Management System is no longer a luxury but a necessity in today’s fast-paced business environment. Whether you’re looking to improve accuracy, streamline processes, or save costs, an IMS offers the tools to take your inventory management to the next level.